Product Description

High-Performance Rubber Foam Insulation Tube Production Line: Efficient & Premium Quality

Huashida is proud to present its Rubber Foam Insulation Tube Production Line, incorporating the latest technologies and the most advanced automated continuous production processes. We utilize high-performance nitrile butadiene rubber and polyvinyl chloride (NBR, PVC) as primary raw materials, complemented by a variety of high-quality auxiliary materials, to manufacture soft, highly efficient insulation and energy-saving materials through a unique foaming process.

Production Line Advantages

Our production line stands out among its domestic and international counterparts, boasting significant features:

-

High Extrusion Output & Superior Quality: Achieves efficient production while ensuring top-tier product quality.

-

Automatic Temperature Control: Precisely managed temperatures guarantee production stability and product consistency.

-

Low Energy Consumption: Optimized design effectively reduces operational costs.

-

Inverter Control: Enables precise speed control, enhancing both production efficiency and safety.

This line surpasses similar equipment globally in extrusion speed, degree of automation, and safety performance. Furthermore, its molding technology, structural performance, and vulcanizing quality are all at a world-leading level.

Product Characteristics: Exceptional Rubber Foam Insulation Material

The rubber foam insulation material produced by this line is a closed-cell elastic material, offering a range of outstanding properties:

-

Excellent Softness: Easy to install and process.

-

High Flexibility: Resists bending well and is not easily damaged.

-

Cold & Heat Resistant: Maintains stable performance across a wide temperature range.

-

Flame Retardant: Enhances safety in use.

-

Waterproof: Effectively prevents moisture penetration.

-

Low Thermal Conductivity: Significantly reduces heat loss, ensuring high energy efficiency.

-

Shock & Sound Absorption: Helps minimize noise and vibration.

Broad Application Fields

Due to its exceptional comprehensive properties, rubber foam insulation material finds wide application across various industries and sectors requiring insulation, cooling, and noise/vibration reduction:

-

Central Air-Conditioning Systems: Ideal for insulating pipes and containers.

-

Construction Industry: Provides insulation for hot and cold media pipes and containers, reducing energy consumption.

-

Chemical, Pharmaceutical, Textile, Metallurgy: Offers effective insulation for industrial pipes and equipment.

-

Shipbuilding, Vehicles, Appliances: Provides efficient insulation and vibration damping solutions.

-

Fitness & Medical Equipment: Serves as an ideal insulation or protective material, enhancing comfort and safety.

-

Solar Heating Systems: Insulates indoor and outdoor pipes, boosting system efficiency.

By choosing Huashida's Rubber Foam Insulation Tube Production Line, you will acquire high-performance, versatile insulation materials, helping your projects achieve lower cold and heat loss for higher energy efficiency standards.

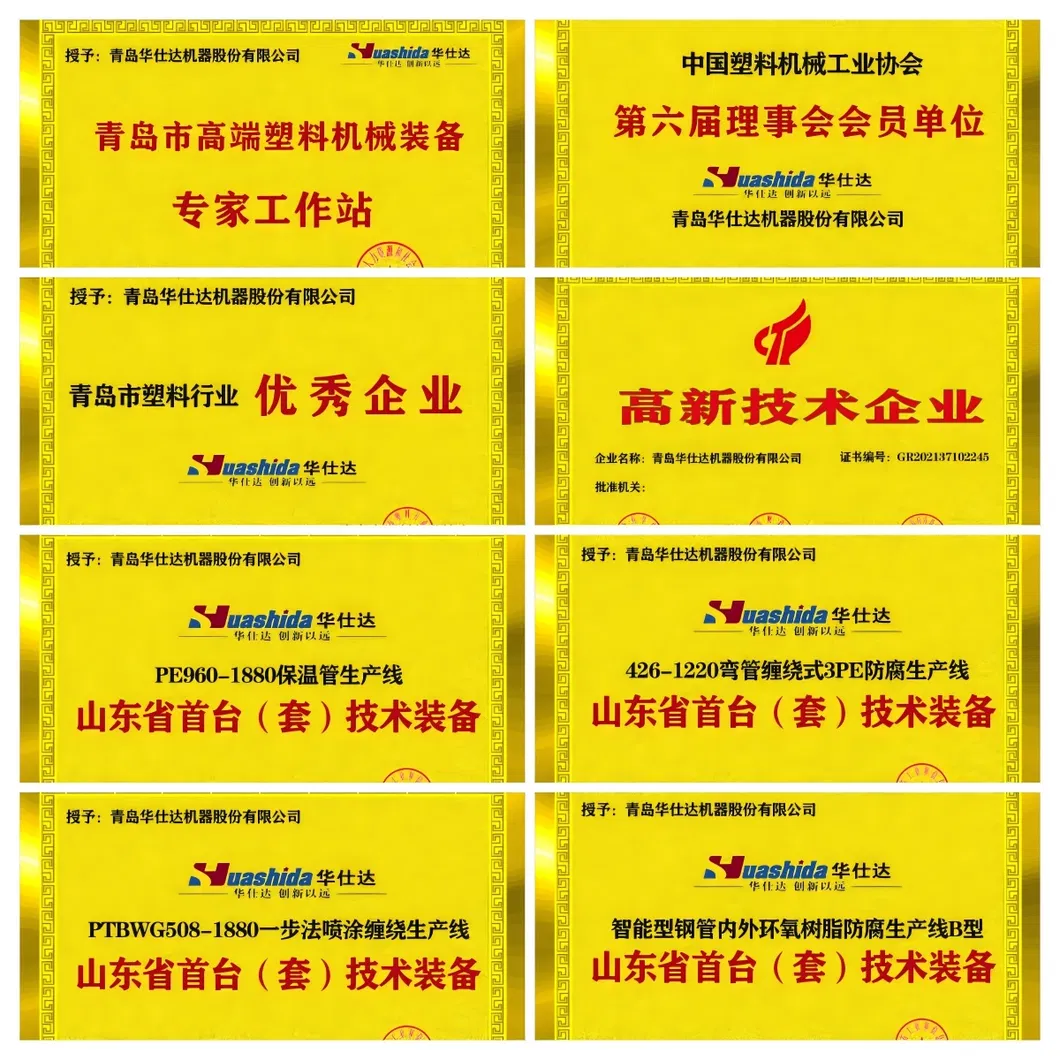

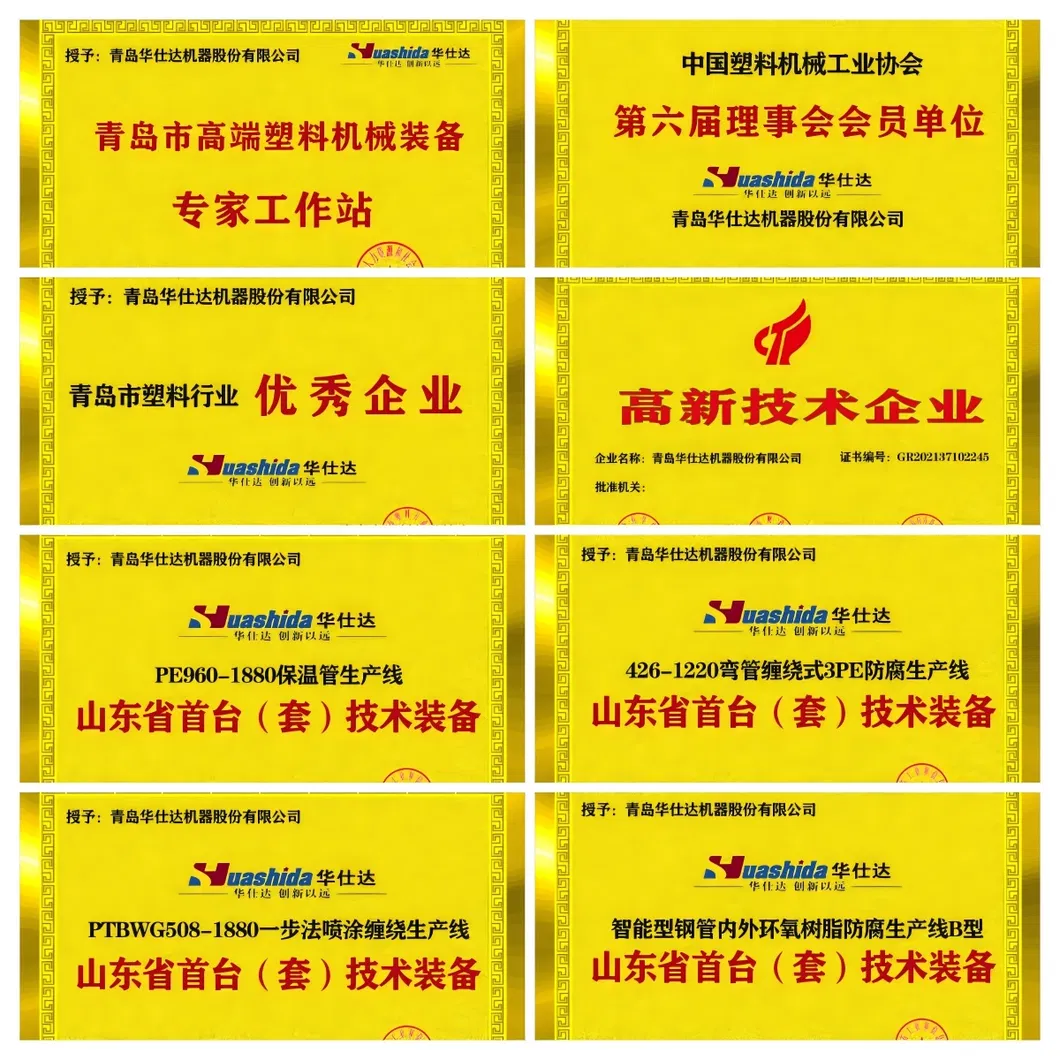

Qingdao Huashida Machinery Co., Ltd was established in 2003. Since its inception, Huashida has focused on plastic polyurethane insulation pipe production line, 3PE anti-corrosion pipe production line, large diameter underground pipe production line and plastic pipe joints for 20 years. We always attach great importance to research and development,collaborating closely with Beijing University of chemical technology, Qingdao university of technology and scientific research institutions. by absorbing advanced technology home and abroad, after 20 years of endeavor we now rank one of the top 3 manufacturers in the industry in China. Huashida machines have been well received in Saudi Arabia, Kazakhstan, Uzbekistan, United Arab Emirates, Turkey, Russia, etc.

Exhibition

client

packaging

Certifications

Votre message doit contenir entre 20 et 3 000 caractères!

Votre message doit contenir entre 20 et 3 000 caractères! Merci de consulter vos emails!

Merci de consulter vos emails!  Votre message doit contenir entre 20 et 3 000 caractères!

Votre message doit contenir entre 20 et 3 000 caractères! Merci de consulter vos emails!

Merci de consulter vos emails!