Ligne de production automatisée d'extrusion de type O pour tubes en acier revêtus anti-corrosion 3LPE

Description du produit

LeMachine de revêtement anti-corrosion par extrusion de type Ocomprend les systèmes de transmission de tuyaux en acier, de soufflage par tir, de collecte de poussière, de chauffage, de pulvérisation électrostatique de poudre, de revêtement PE et d'adhésif, de refroidissement à l'eau, de coupe des bords, de commandes hydrauliques,et systèmes électriques.

LePièces en acier revêtues d'un revêtement anticorrosion 3LPEoffre une excellente résistance chimique aux acides, aux bases, aux sels et aux oxydants, ce qui le rend adapté au transport moyen dans divers environnements.ainsi que des systèmes d'approvisionnement en eau et de drainage.

Processus technologiques

Pièces de chargement- Je ne sais pas.tuyaux convoyeur à vis- Je ne sais pas.élimination de la rouille- Je ne sais pas.chauffage à fréquence intermédiaire- Je ne sais pas.revêtement en poudre d'époxy- Je ne sais pas.revêtement adhésif en polyéthylène de couche externe- Je ne sais pas.pulvérisation de refroidissement- Je ne sais pas.tuyaux convoyeur à vis- Je ne sais pas.finitions de tuyaux de broyage- Je ne sais pas.tuyau de déchargements

Paramètres du produit

- Gamme de tuyaux en acier: 50 mm - 426 mm

- Capacité de traitement: ≥ 150 m2/h

- Niveau de nettoyageJe vous en prie.5

- Matériaux de production: poudre d'époxy, adhésif, polyéthylène

Nos avantages

- Technologie de pointe: utilise des méthodes de pointe.

- Fonctionnement stable: Assure une performance fiable.

- Automatisation élevée: réduit les coûts de main-d'œuvre.

- Assurance qualité: Excellentes propriétés anticorrosion, répondant aux normes internationales.

- Des solutions complètes: offre la conception, l'installation, la mise en service et la formation.

- Expérience mondiale: 389 ensembles de production dans le monde.

- Une équipe d'experts: 9 ingénieurs supérieurs.

- Facilité haut de gamme: station de travail de machines plastiques avancées en Chine.

Liste des équipements principaux

| Je ne veux pas. |

Nom |

Réglage |

| A. Équipement de dépoussiérage |

| 1 |

Équipement de transport par tuyauterie |

1 |

| 2 |

Machine à nettoyer par soufflage |

1 |

| 3 |

Collecteur de poussière de cyclone |

1 |

| 4 |

Collecteur de poussière à impulsions |

1 |

| 5 |

Ventilateur d'échappement centrifuge |

1 |

| 6 |

Système de commande PLC pour les équipements de déshydratation |

1 |

| B. Équipement de revêtement |

| 1 |

Équipement de transfert de revêtement |

1 |

| 2 |

SI appareil de chauffage |

1 |

| 3 |

Dispositif de pulvérisation |

1 |

| 4 |

Sécheuse à chargement automatique |

2 |

| 5 |

SJ-65/30 Extrudeuse |

1 |

| 6 |

Extrudeuse SJ-90/30 |

1 |

| 7 |

Détecteur d'extrudeurs adhésifs à fusion chaude |

1 |

| 8 |

Moule de tête d'extrudeuse en PE |

1 |

| 9 |

Dispositif de revêtement pour adhésif à fond chaud/PE |

1 |

| 10 |

Équipement de refroidissement par pulvérisation |

1 |

| C. Je ne sais pas.Équipement de plateforme |

| 1 |

Plateforme de tuyauterie en acier |

1 |

| 2 |

Plateforme de transition après élimination de la rouille |

1 |

| 3 |

Plate-forme de stockage des tubes du produit |

1 |

| 4 |

Équipement hydraulique |

2 |

| D. Je ne sais pas.Équipement de rainure |

| 1 |

Machines à béton de PE |

2 |

| 2 |

Machines hydrauliques de levage et de tournage |

1 |

| 3 |

Équipement hydraulique |

1 |

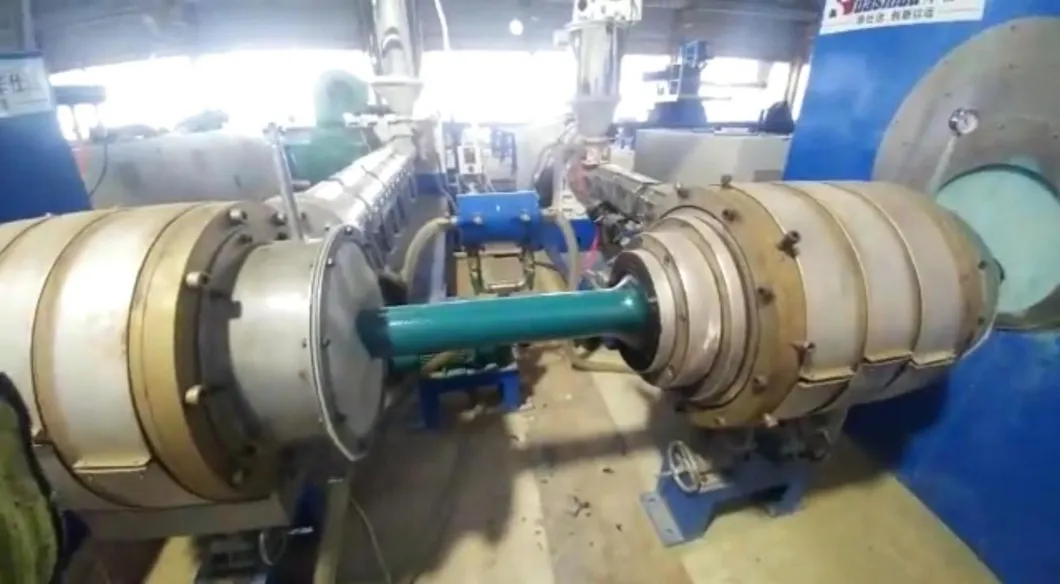

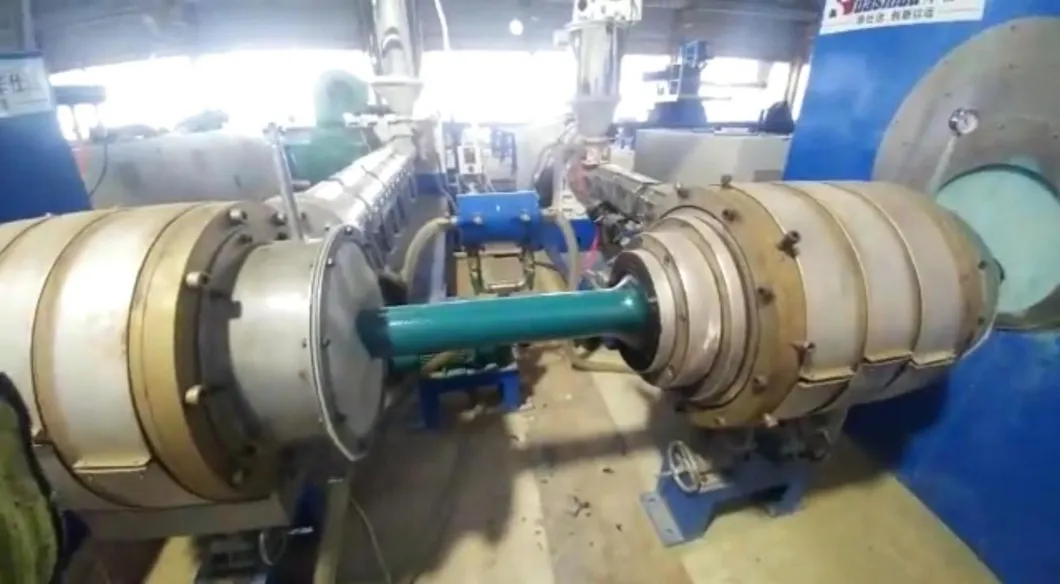

Des photos détaillées

Cas de clients

Profil de l'entreprise

La société Qingdao Huashida Machinery Co., LTD.est un fabricant d'une gamme de machines de tuyauterie en plastique, de machines de tuyauterie municipale, de machines d'isolation et anti-corrosion, ainsi que de matériaux de joints, dont l'expérience s'appuie sur 21 ans.

Principaux produits:

- Ligne de production de tuyaux en PEHD (110-2000 mm)

- Ligne de production de tubes rigides préisolés

- Ligne de production de tubes préisolés flexibles (PERT)

- Ligne de revêtement anti-corrosion pour tuyaux en acier FBE/2LPE/3LPE

- Ligne de déblaiement de tuyaux en acier

- Ligne de production de tuyaux sous pression en PE/tubes d'alimentation en gaz d'eau

- Ligne de production de cartes/feuilles/géomembranes en plastique PP/PE

- Ligne de production de tubes/plaques d'isolation thermique en PVC NBR

- Matériaux anti-corrosion pour pipelines: manchons de revêtement de joints rétrécissants par la chaleur, manchons de joints soudables par électro-fusion, pistolets de soudage portables, tiges de soudage PE/PP.

Nous desservons plus de 400 clients à l'étranger et exportons vers des pays tels que le Kazakhstan, l'Ouzbékistan, l'Iran, la Turquie, la Russie et le Nigéria.

Résumé de l'usine

Notre équipe.

Livraison

Exposition

La société de machines Huashida

Je vous en prie.

Pour les téléphones portables:8615902963037

Le numéro d'identifiant de l'établissement

Les données sont fournies par les autorités compétentes de l'UE.

Votre message doit contenir entre 20 et 3 000 caractères!

Votre message doit contenir entre 20 et 3 000 caractères! Merci de consulter vos emails!

Merci de consulter vos emails!  Votre message doit contenir entre 20 et 3 000 caractères!

Votre message doit contenir entre 20 et 3 000 caractères! Merci de consulter vos emails!

Merci de consulter vos emails!